Field Vane Shear Test Service

Standard Test Method for Field Vane Shear Test in Cohesive Soil

ASTM D 2573 – 94

1.1 This test method covers the field vane test in soft, saturated, cohesive soils. Knowledge of the nature of the soil in which each vane test is to be made is necessary for assessment of the applicability and interpretation of the test.

1.2 The values stated in inch-pound units are to be regarded as the standard. The SI units given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

2. Summary of Test Method

The vane shear test basically consists of placing a four-bladed vane in the undisturbed soil and rotating it from the surface to determine the torsional force required to cause a cylindrical surface to be sheared by the vane; this force is then converted to a unit shearing resistance of the cylindrical surface. It is of basic importance that the friction of the vane rod and instrument be accounted for; otherwise, the friction would be improperly recorded as soil strength. Friction measurements under no-load conditions (such as the use of a blank stem in place of the vanes, or a vane that allows some free rotation of the rod prior to loading) are satisfactory only provided that the torque is applied by a balanced moment that does not result in a side thrust. As torsional forces become greater during a test, a side thrust in the instrument will result in an increase in friction that is not accounted for by initial no-load readings. Instruments involving side thrust are not recommended. The vane rod may be of sufficient rigidity that it does not twist under full load conditions; otherwise a correction must be made for plotting torque-rotation curves.

3. Significance and Use

3.1 This test method provides an indication of in-situ shear strength.

3.2 This test method is used extensively in a variety of geotechnical explorations, such as in cases where a sample for laboratory testing cannot be obtained.

4. Apparatus

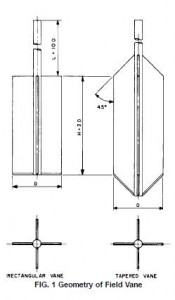

4.1 The vane shall consist of a four-bladed vane as illustrated in Fig. 1. The height of the vane shall be twice the diameter. Vane dimensions shall be as specified in Table 1. Sizes other than those specified in Table 1 shall be used only with the permission of the engineer in charge of the boring program. The ends of the vane may be tapered (see Fig. 1). The penetrating edge of the vane blade shall be sharpened having an included angle of 90°.

4.2 The vane shall be connected to the surface by means of steel torque rods. These rods shall have sufficient diameter such that their elastic limit is not exceeded when the vane is stressed to its capacity (Note 1). They shall be so coupled that the shoulders of the male and female ends shall meet to prevent

any possibility of the coupling tightening when the torque is applied during the test. If a vane housing is used, the torque rods shall be equipped with well-lubricated bearings where they pass through the housing. These bearings shall be provided with seals to prevent soil from entering them. The torque rods shall be guided so as to prevent friction from developing between the torque rods and the walls of casing or boring.

NOTE 1—If torque versus rotation curves are to be determined, it is essential that the torque rods be calibrated (prior to use in the field). The amount of rod twist (if any) must be established in degrees per foot per unit torque. This correction becomes progressively more important as the depth of the test increases and the calibration must be made at least to the maximum depth of testing anticipated:

4.3 Torque shall be applied to the torque rods, thence to the vane. The accuracy of the torque reading should be such that it will produce a variation not to exceed ±25 lb/ft2 (1.20 kPa) shear strength.

4.4 It is preferable to apply torque to the vane with a geared drive. In the absence of a geared drive, it is acceptable to apply the torque directly by hand with a torque wrench or equivalent. The duration of the test should be controlled by the requirements of 5.3.

5. Procedure

5.1 In the case where a vane housing is used, advance the housing to a depth which is at least five vane

housing diameters less than the desired depth of the vane tip. Where no vane housing is used, stop the hole in which the vane is lowered at a depth such that the vane tip may penetrate undisturbed soil for a depth of at least five times the diameter of the hole.5.2 Advance the vane from the bottom of the hole or the vane housing in a single thrust to the depth at which the test is

to be conducted. Take precautions to make sure no torque is applied to the torque rods during the thrust.

5.3 With the vane in position, apply the torque to the vane at a rate which should not exceed 0.1°/s. This generally

requires a time to failure of from 2 to 5 min, except in very soft clays where the time to failure may be as much as 10 to 15 min. In stiffer materials, which reach failure at small deformations, it may be desirable to reduce the rate of angular displacement so that a reasonable determination of the stress-strain properties can be obtained. During the rotation of the vane, hold it at a fixed elevation. Record the maximum torque. With apparatus with geared drives, it is desirable to record intermediate values of torque at intervals of 15 s or at lesser frequency if conditions require.

5.4 Following the determination of the maximum torque, rotate the vane rapidly through a minimum of 10 revolutions; the determination of the remoulded strength should be started immediately after completion of rapid rotation and in all cases within 1 min after the remoulding process.

5.5 In the case where soil is in contact with the torque rods, determine the friction between the soil and the rod by means of torque tests conducted on similar rods at similar depths with no vane attached. Conduct the rod friction test at least once on each site; this shall consist of a series of torque tests at varying depths.

5.6 In apparatus in which the torque rod is completely isolated from the soil, conduct a friction test with a blank rod

(Note 2) at least once on each site to determine the magnitude of the friction of the bearings. In a properly functioning vane apparatus, this friction should be negligible.

NOTE 2—In some cases it is not necessary to remove the vane for the friction test. As long as the vane is not in contact with the soil, that is, where it is retracted into a casing, the friction measurement is not affected.

5.7 Conduct undisturbed and remoulded vane tests at intervals of not less than 2|n$ ft (0.76 m) throughout the soil profile when conditions will permit vane testing (Note 3). Do not conduct the vane test in any soil that will permit drainage or dilates during the test period, such as sands or silts or in soils where stones or shells are encountered by the vane in such a manner as to influence the results.

SOURCE : www.nosazimadares.ir

Previous Post

Previous Post Next Post

Next Post